SAPPHIRE is now one of the most in-demand materials in watchmaking, but a decade ago, Richard Mille seems to be alone in grasping its true potential for use on an entire watch case – where one was made entirely of sapphire crystal.

The brand invested significant resources in researching and developing new techniques that would elevate its most exclusive calibres in unprecedented ways.

Richard Mille’s ground-breaking use of sapphire has redefined the boundaries of horological innovation.

By harnessing the unique properties of this extraordinary material, the brand has created timepieces that are both technically impressive and aesthetically stunning.

For instance, the RM 056 Tourbillon Split-Seconds Chronograph Sapphire, introduced in 2012, showcased the brand’s mastery of sapphire, pushing the limits of material science and horological engineering.

Balance between art and science

This bold move, driven by innovation and a relentless pursuit of perfection, elevated the brand to iconic status.

Sapphire, renowned for its exceptional hardness and scratch resistance, offers a level of durability unmatched by traditional materials.

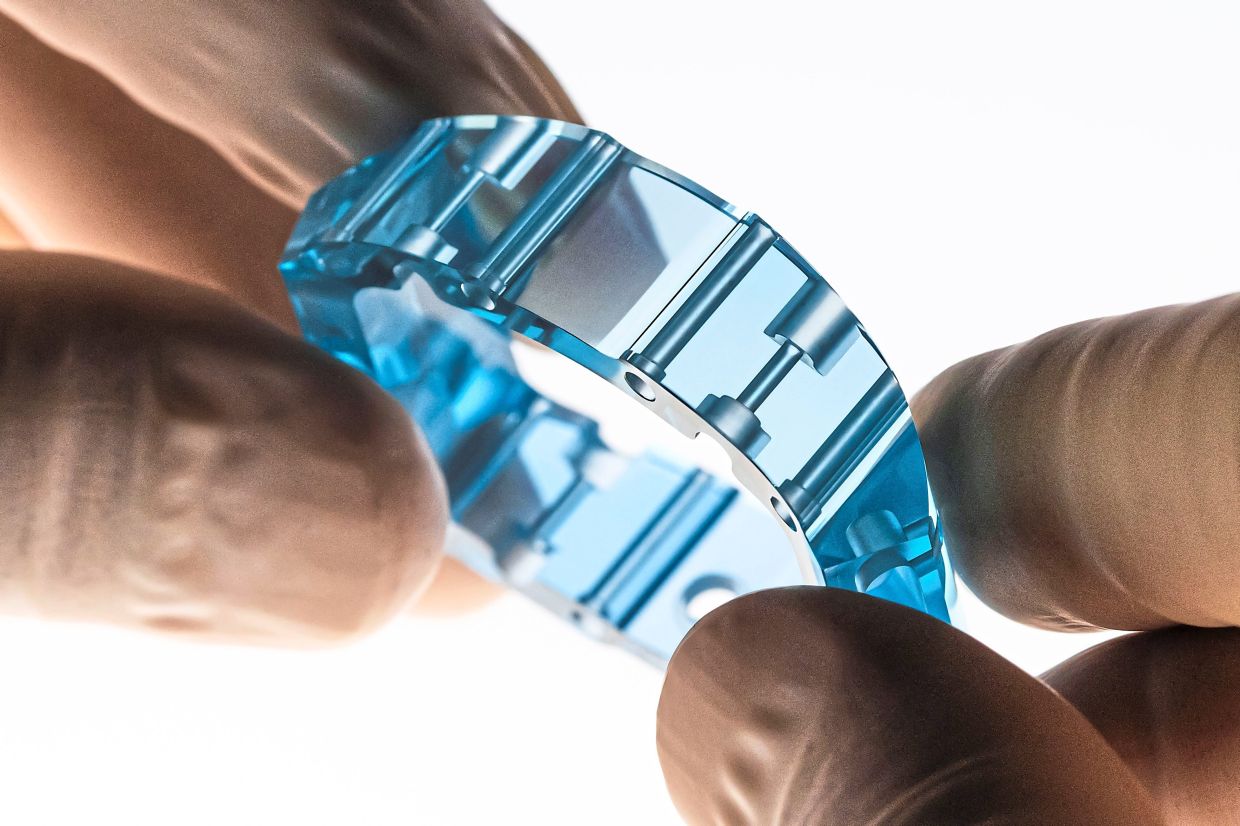

The main benefits of sapphire are its transparency and radiance, which highlight every detail of the brand’s calibres while subtly capturing the light with cases machined entirely from this material.

This timeless, crystalline setting deserved the full attention of engineers and design studios.

It is simultaneously functional, aesthetic and sensory.

Its chemical composition gives it an exceptional score of 9 on the Mohs scale of mineral hardness, just behind diamond which tops the list.

Its outstanding properties make it impact- and scratch-resistant, while its soft, tactile surface gives it a warm and comfortable feel on the wrist.

This unique material, the product of precise expertise, embodies both preciousness and innovation.

The material is a synthetic form of aluminum oxide − one of the hardest substances, second only to diamond.

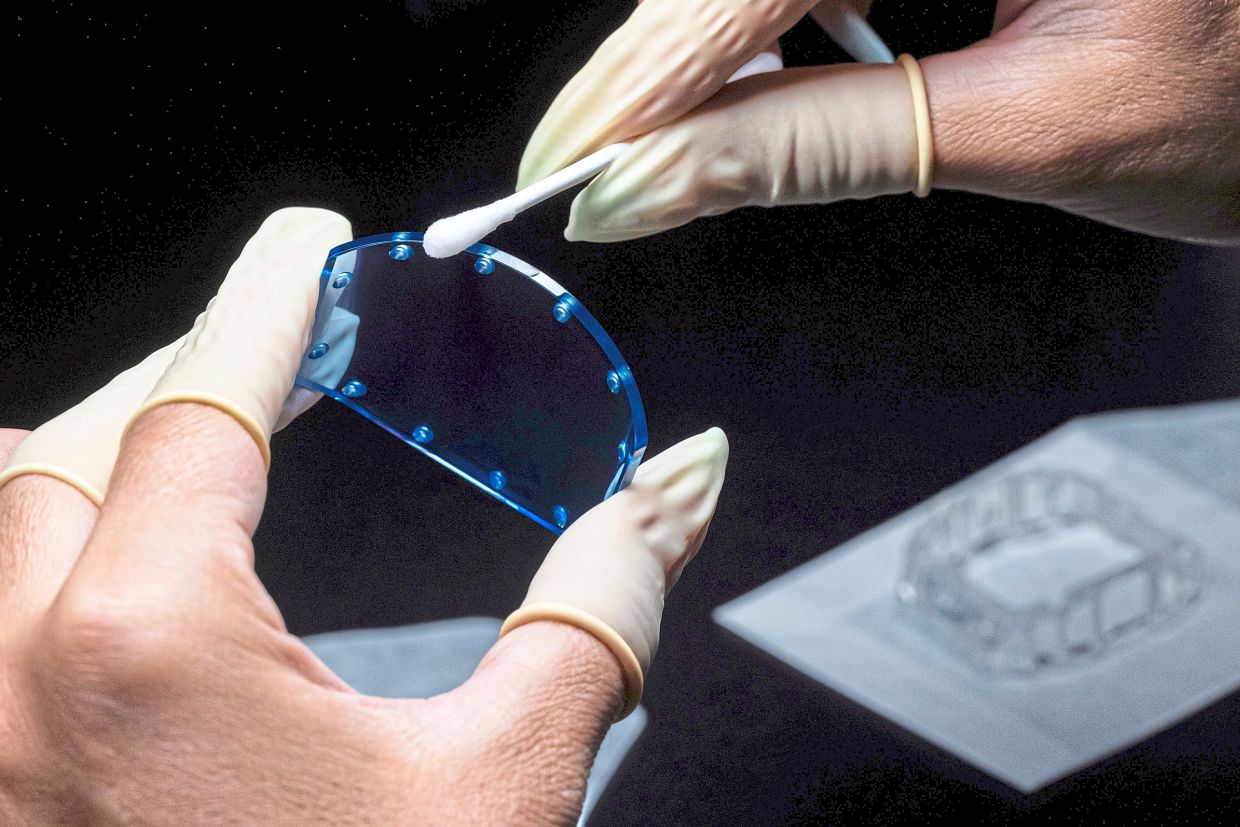

As a result, cases have to be machined with diamond-tipped tools.

It can take hundreds of hours to machine the material, and room for error is so slim that a small mistake can destroy the entire piece.

Coloured sapphire is even more difficult because achieving consistency in the hue is highly challenging and increases production time. One case can take over 1,000 hours just for the machining.

Richard Mille has pushed the boundaries of horological innovation with its introduction of coloured sapphire.

The slightest deviation in temperature or growth rate can significantly impact the final colour, making each coloured sapphire a unique masterpiece.

A revolution in watchmaking

As in the optical and electronics sectors, the watchmaking industry uses synthetic sapphire, which has exactly the same chemical composition, physical properties and crystalline structure as its natural counterpart, but with the added advantage that it can be produced in blocks large enough for creating Richard Mille cases.

A sapphire block weighing several dozen kilogrammes is needed to make the three parts of a single curved Richard Mille watch case.

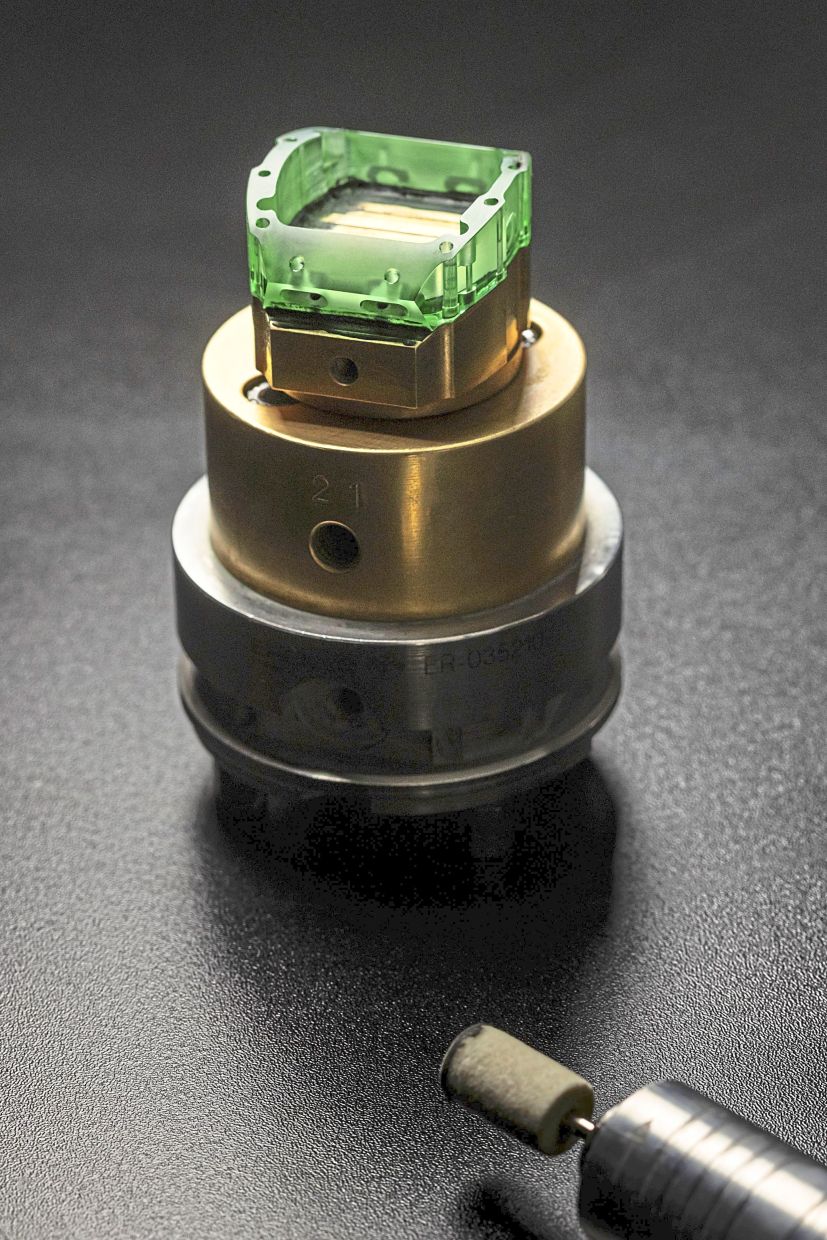

Working with its Swiss partner Stettler AG, the brand uses the Kyropoulos method to produce this material.

This involves heating aluminium oxide to between 2,000°C and 2,050°C in a controlled atmosphere; a small sapphire crystal acts as a seed, encouraging the synthetic crystal to grow slowly around, in a process that can take several weeks.

The constraints inherent to the use of synthetic sapphire at Richard Mille are unprecedented.

Firstly, the complex curved shapes of its cases meant that new, particularly demanding machining and finishing processes have had to be introduced.

The material’s hardness of 2,000 Vickers and its extreme rigidity during cutting and assembly impose tolerances of just a few microns.

In addition, a sapphire case requires more than 1,000 hours of milling and polishing.

While the majority of sapphire crystals produced are round, producing Richard Mille’s tonneau-shaped watches introduces a new level of complexity and cost increases.

For this exact reason, it is rare, even at the top end of the watch spectrum, to see sapphire being used in creative ways that Richard Mille does.

Producing coloured sapphires involves a process that is even more complex than for transparent sapphire: these stones are created by carefully incorporating metal oxides into the material’s crystalline lattice.

However, a coloured crystal is more sensitive to the heating and growth process than its colourless counterpart.

Therefore, developing a new shade like lilac involves a multitude of trials before the exact shade can be approved. --- Compiled by RINA AHMAD SAPIUDDIN