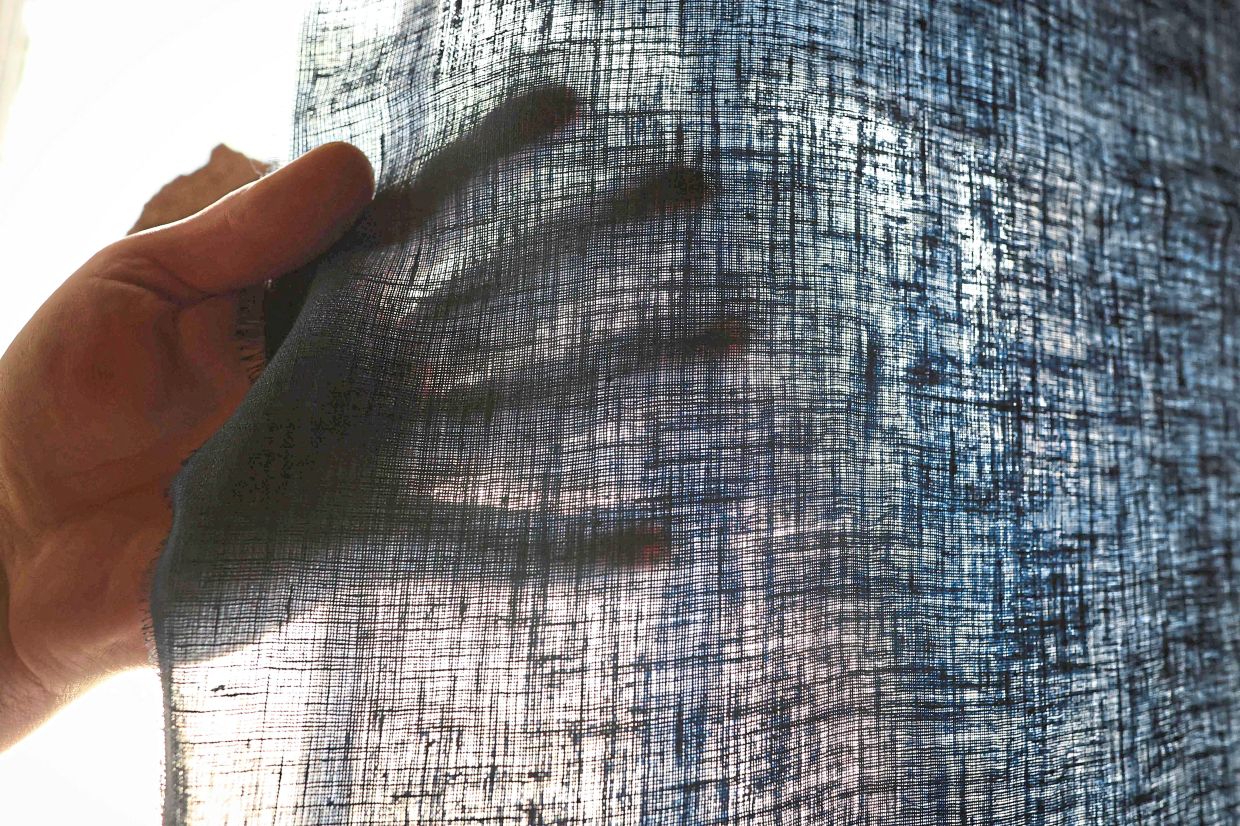

Smyth working at the Linen beetling mill in Upperlands, County Londonderry, Northern Ireland. Managers at William Clark & Sons, founded in 1736, say the company has a bright future as interest grows in traditional beetled linen from high-class fashion designers, with an eye on sustainability. — AFP

THE noise is deafening and the work can be lonely, but to William Smyth, who toils in the world’s last commercial linen “beetling” mill, his job is unique.

“There’s nothing modern about it, I’m doing the same now as they were doing 100 years and more ago,” said Smyth, 59, at the mill in Upperlands, a village some 70km west of Belfast in Northern – the last commercial beetling operation in existence.

“Nobody’s come up with anything to make it any easier, there’s no other way of getting the finish on that cloth,” he said of the traditional method which creates a silky sheen on the linen.

Managers at William Clark & Sons, founded almost 300 years ago in 1736, say the company has a bright future as interest grows in traditional beetled linen from high-class fashion designers, with an eye on sustainability.

The din comes from the giant mallet-type hammers – the “beetles” – on a 150-year-old beetling machine, an antiquated relic of a once thriving Irish industry.

Dangling from a beam, around 40 beetles relentlessly pound the woven linen fed by Smyth through the machine’s cast-iron engine that powers a rotating roll.

Up to 140 hours of beetling creates a fabric with a lustrous and hard-wearing finish.

The finished product has captured renewed interest in recent years from top designers such as fashion house Alexander McQueen and Northern Irish designer Amy Anderson.

The handsome riverside stone building houses three working engines and is the last commercially-run beetling mill in the world, says Andrew Wilson, a businessman who invested in the mill earlier this year.

“Beetling mills used to be dotted along rivers all over Ireland; unfortunately this is the last one left,” he said.

The last-minute investment saved the mill after it went into administration in December and kept Smyth’s endangered craft from extinction, Wilson said.

“William’s skill set was about to disappear, we wanted to keep it alive,” he said.

Wearing protective ear-muffs, Smyth, who has worked with linen for 40 years and as a beetler for five, nimbly moves between the engines, tugging and smoothing the moving rolls of linen.

“I have to keep an eye on it when it’s on the machine, make sure it doesn’t slip, and watch for creases and nips,” he said.

Starting at dawn, Smyth toils alone 10 hours a day, loading and unloading the cloth from each machine.

Before the process the linen is stiffened with starch and after beetling, Smyth hauls the rolls upstairs and hangs them to dry from the roof beams for about a month.

“When it dries out, it’ll go all crispy and wrinkly. I take it back down on the machines again to take the wrinkles out of it. And that’s it, it’s finished,” he said.

“I enjoy seeing how the cloth changes,” he said.

From its emergence in the 18th century, the linen industry flourished in Ireland, forming the backbone of the economy and driving the growth of cities such as Belfast and villages like Upperlands.

In the countryside, farmers grew the flax which was woven, bleached and dyed close to the local riverside mill where water provided power.

By the mid-19th century, Belfast was shipping linen tablecloths, shirts and handkerchiefs around the world, earning the nickname “Linenopolis”.

But the industry declined in the 20th century as the labour-intensive fabric was replaced by cheaper artificial fibres.

William Clark & Sons has held onto a loyal niche customer base for beetled linen including fashionable tailors in London’s Savile Row and clients in Japan, manager Kevin Devlin said.

“It’s used inside the garment at the seams and the joints, it’s invisible to the wearer of the clothing but adds a lot of strength,” he said.

“If you’re buying a high-class suit and you want the sleeve to last a long time, then beetled linen is the material of choice.”

More expensive than regular linen, Devlin still sees commercial potential for growth.

“We hope that more creatives come to appreciate its finish and its heritage,” he said.

That could mean an apprentice is hired to help Smyth, he added.

“We need to find the right person, with a calling for this traditional processing, and not be put off by manual work for long hours and the rumble of the beetles,” he said. — AFP